What’s behind this MTP?

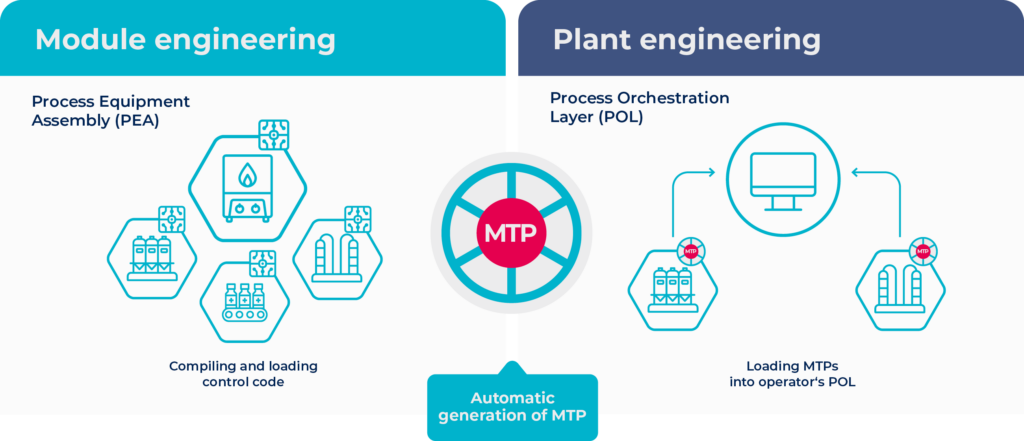

Ever shorter product life cycles in the process industry necessitate innovations in the engineering and operation of equipment. The design of modular process engineering equipment has already been tested by industry. This has significantly reduced engineering costs. Yet integrated modular engineering has failed because controllers from different manufacturers couldn’t be used together within one production line. So the advantages of a modular design are offset by new expenditure relating to integration of the modules, subsequently referred to as a process equipment assembly (PEA) according to VDI/VDE Standard 2776. A manufacturer-independent description of the automation of PEAs was therefore developed and standardised within VDI/VDE/NAMUR Standard 2658. This description permits several PEAs with controllers from different manufacturers to be integrated into any process orchestration layer (POL). This refers to modular plants’ higher-level control and management system, whose functionalities are similar to a process control system. A PEA is described using a Module Type Package (MTP).

In this case, all the necessary information required for integration into a POL is described within the MTP. The basis for this is a description of all PEA variables to be communicated via the OPC UA server, which acts as a communication interface to the controller. The MTP description also includes an operating screen as a structural description, services as encapsulated process functionalities and other aspects relating to alarms and diagnostics. The MTP is generated by the PEA manufacturer. The plant operator then imports it as an AutomationML file into the process control level systems.

Similar to a USB driver, the MTP enables PEAs to be quickly integrated into modular plants to enable plug and produce.

Further literature on MTPs

| Module-based production in process automation. MTP for efficiency improvement in modular process equipment | |

|---|---|

| Autor:in: | A. Menschner |

| Datum: | Oktober 2020 |

| Process INDUSTRIE 4.0: The Age of Modular Production | |

|---|---|

| Autor:in: | ZVEI-Zentralverband |

| Datum: | März 2019 |

| VDI/VDE/NAMUR 2658: Automation engineering for modular plants in the process industry | |

|---|---|

| Autor: | VDI/VDE/NAMUR |

| Datum: | ab Oktober 2019 |