MTP-ControlEngine

Provide more flexibility.

Increase the flexibility of your laboratory, technical center and production facilities by at least 50%. This enables you both to execute different processes and to produce different products on the same production line.

Using our MTP-ControlEngine.It provides the behaviour described in the VDI/VDE/NAMUR 2658 standard in such a way that the corresponding data structures can be implemented on any device suitable for this purpose, without the need to develop them yourself – it also runs on our MTP-Box!

Our MTP-ControlEngine is delivered as a C++ software development kit (SDK), which runs platform-independently on Linux, Windows and BSD. Any field device equipped with sufficient computing power can quickly be made MTP-capable.

This imparts your device with additional, essential functionality, which adds value for your customers without changing or disclosing existing functionalities.

Test now!

Our software library is now available for free download and testing! Developers, researchers and the curious are welcome to explore it. Please note our terms and conditions for use. Experience the power of the Control Engine using a simple and practical example without any prior knowledge.

Who benefits

module vendors

plant operators

engineering tool vendors

control system manufacturers

field device vendors

plant manufacturers

Your advantages

A perfect match

Functions irrespective of architecture (compatible with x86, AMD64, ARM, ARM64, MIPS, etc.).

Easy to implement

Our MTP-ControlEngine was developed as an (RT-) OS-independent API.

Always the latest version

It always remains up to date and compliant with the VDI/VDE/NAMUR 2658 standard, because SEMODIA is involved in shaping this standard.

Reach new horizons

Enables you to quickly and profitably enter the MTP market.

How it works

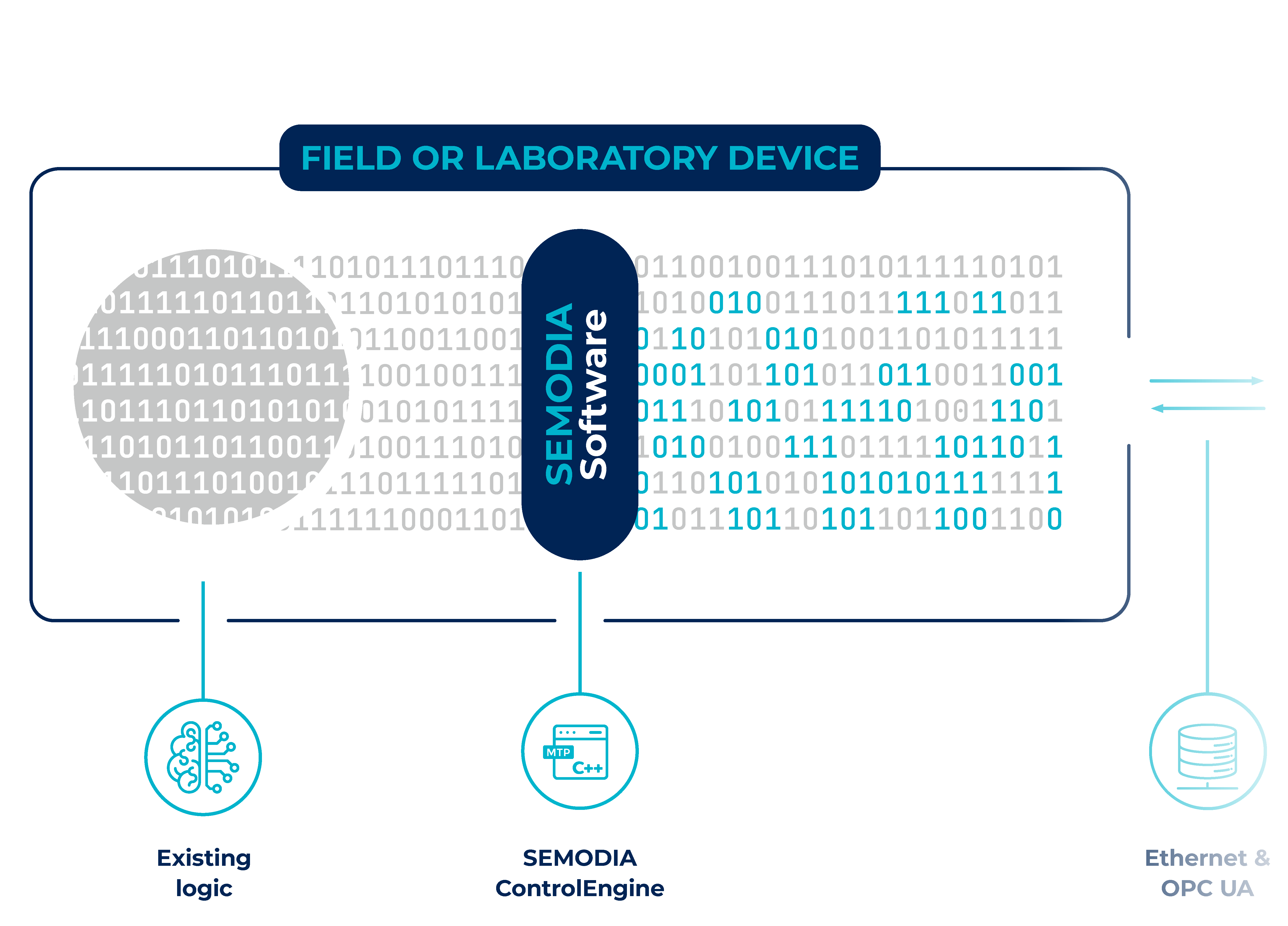

- Our MTP-ControlEngine runs directly on your field or laboratory equipment without changing or disclosing existing functionalities.

- A suitable MTP that describes the functionalities for the field or laboratory equipment is generated for the MTP-ControlEngine.

- The MTP is in the format of a text file and is similar to a printer driver.

- All important module data is available in universal form after connection via our MTP-ControlEngine and is ready for you to use.

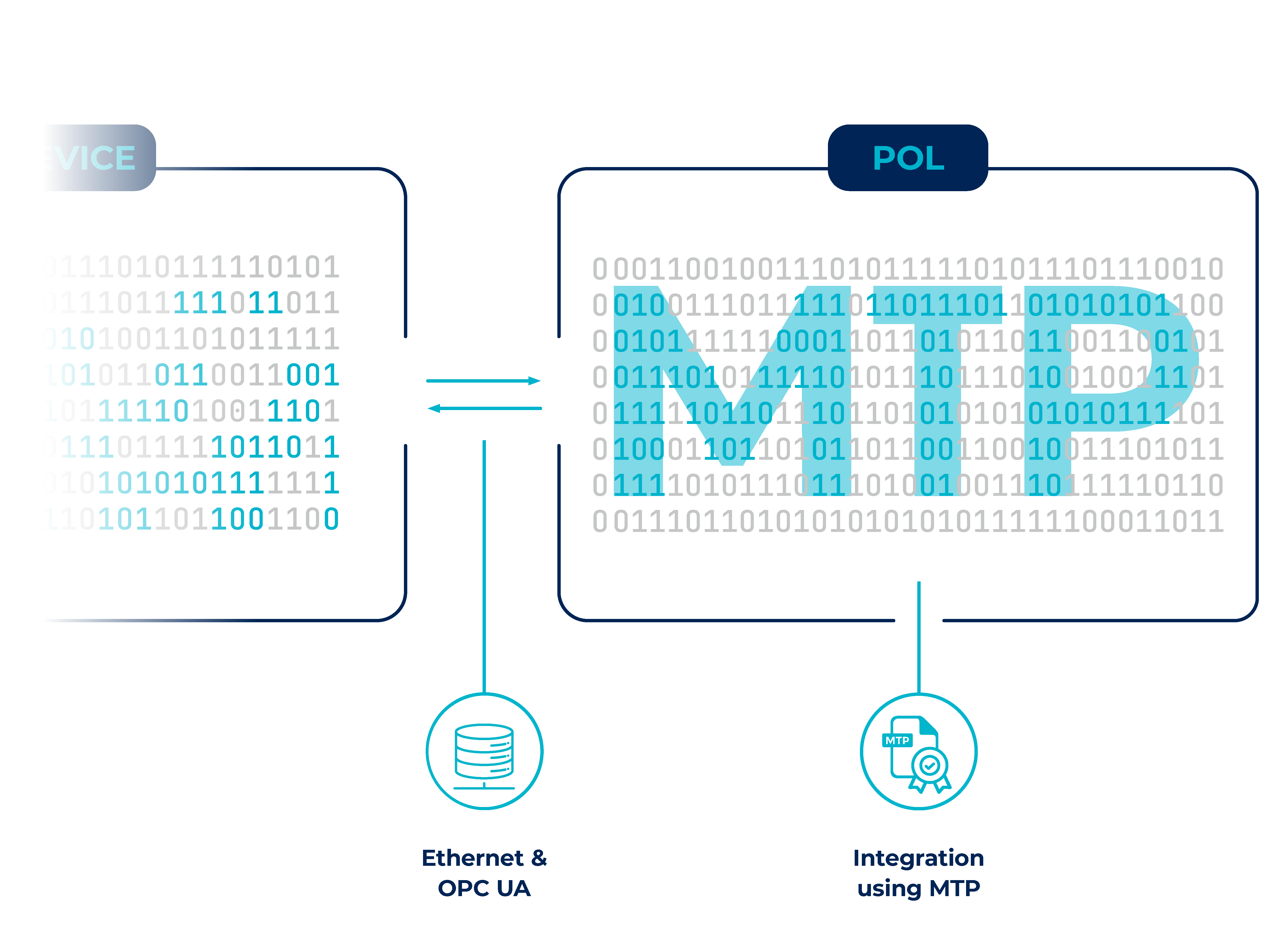

- The supplied MTP can be integrated into any POL.

- The necessary data points for MTP-compliant communication are provided via an OPC UA server, which either already exists on your device or is supplied with our MTP-ControlEngine.

- Fast and flexible integration by means of MTP results in a massive time saving.

- MTP-compliant communication between the device and POL runs via Ethernet & OPC UA after MTP integration into your POL.

Technical details

Our MTP-ControlEngine is not hardware bound and can be used on any device.

The core of our MTP-ControlEngine contains the supplied SDK to provide behaviour compliant with VDI/VDE/NAMUR 2658. Existing communication interfaces in the target application can be reused directly. If not already available, protocol-specific drivers and an OPC UA communication server can also be supplied.

With embedded in mind, MTP-ControlEngine is developed based on architecture-independent C++ code for maximum compatibility with common systems and for platform independence. This enables use of the respective preferred architecture (x86, AMD64, ARM, ARM64, MIPS, …)

Do you want to know how you can benefit from our MTP-ControlEngine?

We are looking forward to your contact request and we will contact you immediatly.